Textile wet processing

Textile

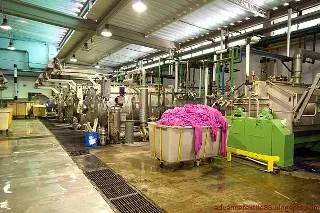

wet processing is one of the major streams in textile engineering refers to

textile chemical processing and applied science. It is usually done on the

manufactured assembly of interlacing fibers, filaments, or yarns having a substantial surface area in relation to their thickness, and adequate

mechanical strength to give it a cohesive structure.

An alternative way to say, the wet process is done on manufactured fabric. The

processes of this stream are carried out in an aqueous stage and thus it is

called a wet process which usually covers pretreatment, dyeing, printing, and

finishing. All of these stages are required an aqueous medium that is created

by water. These processes require plenty of water every day. It is estimated

that, on average, almost 100-110 liter of water is used to process only 1 kg of

textile goods. Water can be of various qualities and attributes. Not all kinds

of water can be used in the textile process, it must have certain characteristics,

quality, color, and properties to be used in the textile process. That is why

wet processing is concerned with water.

Some dyeing process

Dyeing

is the process of adding color to textile products such as fiber, yarn, and

fabrics. It is usually made in a special solution containing dyes and certain

chemical ingredients. Dye molecules have an unnecessary chemical bond with the

fiber molecules after dyeing. Temperature and time control pigmentation are the

two main factors. There are different classes of dyeing, all types of dyeing

are as follows-

Solution dyeing

Solution

dyeing is also called dope or span dyeing, it is the process of adding pigment

or dissolved pigment to the spinning product before it comes out of the

solution through the spinneret solution. Only the fibers produced can be dyed

with a solution. It is used for hard-to-dye fibers such as olefin fibers and

for dyeing fibers for the final color that require excellent coloring

properties. As color dyes become part of the fiber, soluble dyes have good

colorfastness for light, wash, abrasion, perspiration, and bleach. Dyeing at

the solution stage is more expensive, as the equipment has to be thoroughly

cleaned each time a different color is produced. Thus, a small variety of

colors and shades is produced. Besides, it’s hard to stock inventory for each

color. Color decisions should be made early in the manufacturing process. Thus,

this stage of coloring is not usually used for clothing.

Gel dyeing

The

filament fibers that are made using the wet spinning method can be dyed while

the fibers are still in the frozen bath. This method is known as gel dyeing

because the fibers are still soft.

Fiber dyeing

Different

types of dyeing are done for fiber dyeing. The names are indicated on the stage

when it is drawn when the fiber is. All three cover a wide range of fiber

dyeing.

Stock

dyeing is the process of dyeing raw fibers, also called stock, before they are

aligned, blended, and cut into yarns.

Top

dyeing is dyeing to remove short fibers after shortening the worse fibrous

fibers. This stage is known as the wool fiber top. Top dyeing is preferred for

bad fur because the pigment does not have to be wasted on the small fibers

removed during the attachment process.

Tow

dyeing is the dyeing before the filament fibers are cut into short staple

fibers. At this stage, the filament fibers are known as tow.

The

penetration of the dye in the fiber dye is great, so the amount of dye to dye

at this stage is even greater. Fiber dyeing is comparatively more expensive

than yarn, fabric, and garments dyeing. The decision about color selection

should be made early in the production process. Fiber dyeing is commonly used

to dye wool and other fibers that are used to make yarn with two or more dyes.

Fibers for tweeds and fabrics with heather hues are often fibrous hues.

Yarn dyeing

There

are different types of yarn dyeing. Common forms are package form and hank

form. Cotton yarns are mostly dyed in package form, and acrylic or wool yarn is

dyed in hunk form. In the continuous filament industry, polyester or polyamide

yarns are always dyed in package form, while viscose rayon yarns are dyed

partly in hunk form due to technology.

Fabric dyeing

This

is called piece dyeing; it is fabric dyeing after making. This is the most common

method of dyeing for fabric that is economical and densely used for coloring.

The color decision can be made after the fabric is made. Thus, it is suitable

for quick response orders. Dye penetration into dense fabrics may not be good,

so yarn dye is sometimes used to dye on dense fabrics. Different types of

dyeing machines are used to color the pieces. Equipment selection is based on

factors such as dyes and fabric properties, cost, and intended end-use.

Union dyeing

It

is a process of dyeing where a fabric containing two or more types of fibers or

yarns to the same shade so as to achieve the appearance of a solid-colored

fabric. Fabrics can be dyed using single or multiple steps. Union dyeing is

used to dye solid colored blends and combination fabrics normally used for

apparel and home furnishings.

Cross dyeing

Cross

dyeing is a type of dyeing where blend or combine fabrics into two or more

shades by the use of dyes with different affinities for the different fibers.

The cross-dyeing process can be used to create heather effects and to create

plain, check, or striped fabrics. Cross-dyed fabrics can be mistaken for fiber

or yarn-dyed materials because the fabric is not a solid color, considered a

feature of piece-dyed fabrics. It is not possible to visually differentiate

between cross-dyed fabrics and those dyed at the fiber or yarn stage. An

example is cross dyeing blue worsted wool fabric with polyester pinstripes.

When dyed, the wool yarns are dyed blue, whereas the polyester yarns remain white.

Cross dyeing is commonly used with pieces of fabric dyed materials. However,

the same concept applies to yarn and product dyeing. For example, embroidered

silk fabric with white yarn can be dyed and embroidered before placing an order

to dye the product.

Garments dyeing

Garments

dyeing is also known as product dyeing, is the process of dyeing products such

as hosiery, sweaters, and carpet after they have been produced. This stage of

dyeing is suitable when all components dye the same shade. This method is used

for perfect hosiery dyeing as it is knitted using a tubular knitting machine

and then sewn before dyeing. Tufted carpets, with the exception of carpets

produced using solution-dyed fibers, are often dyed after they have been

tufted. This material is not suitable for garments with many elements like

lining, zippers, and knitting threads, as each material can be colored

differently. The exception is tinting jeans with pigments for a vintage look.

Dyeing

is used in tinting, while chemical or mechanical processes are used in

acid-wash and stone-washing. After garment construction, these products are

given the faded or used look by finishing methods as opposed to dying.

Dyeing

at this stage is ideal for a quick response. Many T-shirts, sweaters, and other

types of casual wear are product colored in response to the fashion demand for

certain popular colors. Thousands of garments are constructed from

prepared-for-dye fabric and then dyed to colors that sell best.

0 Comments